ESD energy saving dryers PDP +3 °C

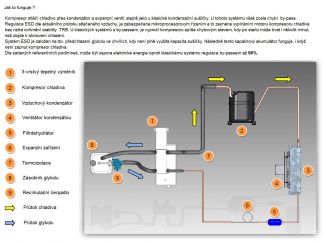

The high efficiency of the ESD series condenser dryers will help you achieve better performance while reducing energy consumption. The patented, high-performance heat exchanger in combination with a thermal mass circuit, in the form of a glycol tank, helps save energy at partial load of the dryer. The refrigerant compressor is automatically switched off and the pressure dew point is not affected, because the pre-cooled capacity of the glycol tank is fully utilized. This results in great energy savings. ESD dryers are reliable and simple. ESD control is provided by a microprocessor control unit.

Higher efficiency, lower costs by up to 96%.

Standard reference conditions

- Ambient temperature 25°C, (max. 45°C)

- Working pressure 7 bar, (max. 16 bar)

- Inlet temperature 35°C, (max. 55°C)

- PDP +3°C, class 4 according to ISO 8573-1

- ESD 54-660 230V/50Hz

- ESD 780-6000 400V/50Hz

- ESD 54-480 are equipped with a timed condensate drain as standard

- ESD 660-6000 are equipped with a lossless condensate drain as standard

Optional options:

- ESD 54-2200 NPT connection

- ESD 2700-6000 ANSI connection

- ESD 54-480 equipped with lossless condensate drain

- ESD 660-600 equipped with timed condensate drain

- ESD 1300-6000 water-cooled condenser

| Model/Data sheet | Flow rate m3/h | Working pressure |

|---|---|---|

| ESD 54 | 54 | 16 |

| ESD 72 | 72 | 16 |

| ESD 108 | 108 | 16 |

| ESD 144 | 144 | 16 |

| ESD 180 | 180 | 16 |

| ESD 240 | 240 | 16 |

| ESD 300 | 300 | 16 |

| ESD 360 | 360 | 16 |

| ESD 480 | 480 | 16 |

| ESD 660 | 660 | 16 |

| ESD 780 | 780 | 13* |

| ESD 1000 | 1000 | 13* |

| ESD 1500 | 1500 | 14 |

| ESD 1800 | 1800 | 14 |

| ESD 2250 | 2250 | 14 |

| ESD 2600 | 2600 | 14 |

| ESD 3600 | 3600 | 13 |

| ESD 4200 | 4200 | 13 |

| ESD 5300 | 5300 | 13 |

| ESD 6000 | 6000 | 13 |

Downloads

- esd_catalogue-fdaa5.pdf [PDF, 2.16 MB]

- esd1500-2250_catalogue-8c800.pdf [PDF, 5.25 MB]