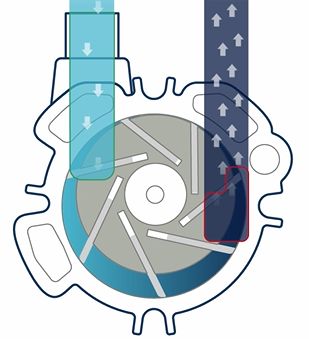

BECKER oil-free rotary vane blowers operate completely without oil. The compression part consists of a rotor eccentrically placed in a stator with graphite vanes with a long service life. The standard equipment includes integrated suction paper filters and control valves, which also function as a safety element, preventing the maximum design overpressure according to the type from being exceeded +1000 to +2000 mbar(g). Flow rate 2-515 m3h expressed at 20 °C and atmospheric pressure.

BECKER oil-free rotary vane blowers operate completely without oil. The compression part consists of a rotor eccentrically placed in a stator with graphite vanes with a long service life. The standard equipment includes integrated suction paper filters and control valves, which also function as a safety element, preventing the maximum design overpressure according to the type from being exceeded +1000 to +2000 mbar(g). Flow rate 2-515 m3h expressed at 20 °C and atmospheric pressure.

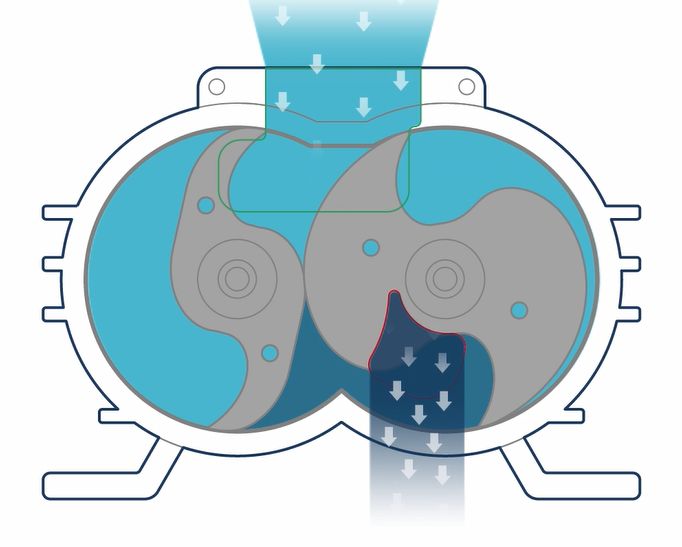

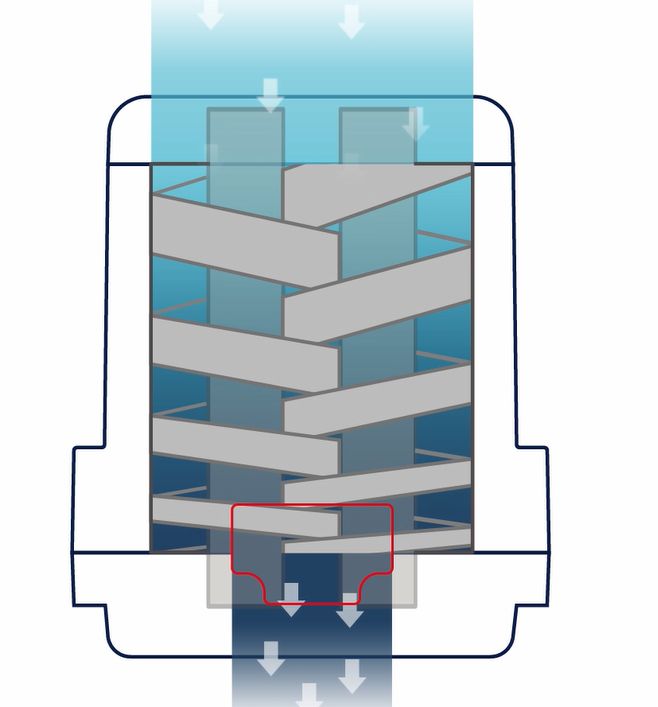

BECKER claw pumps are also known as oil-free, because the pumped medium does not come into contact with oil in the compression section. A small amount of gear oil is enclosed in the gearbox, where the synchronizing gears of the driving and driven shafts are located.

BECKER claw pumps are also known as oil-free, because the pumped medium does not come into contact with oil in the compression section. A small amount of gear oil is enclosed in the gearbox, where the synchronizing gears of the driving and driven shafts are located.

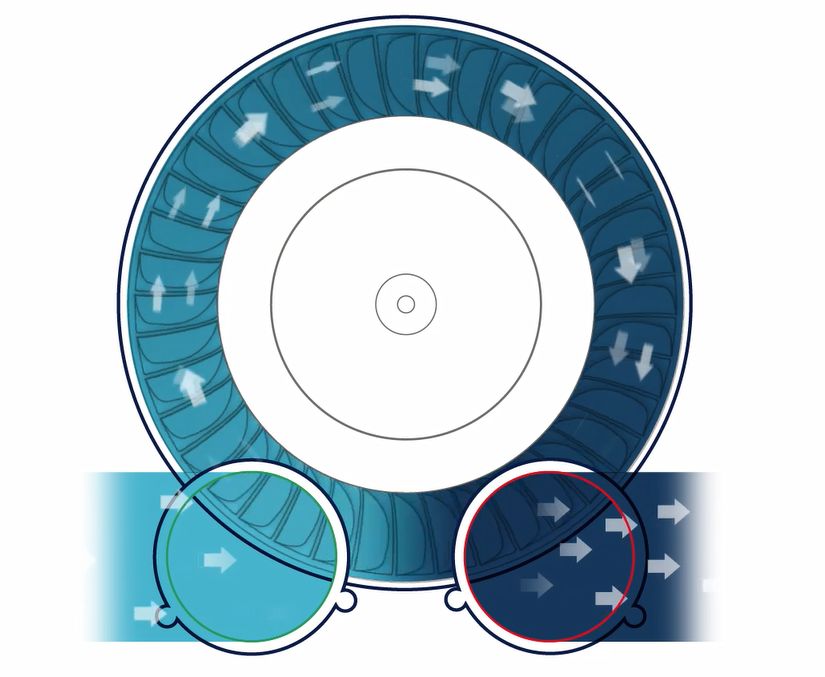

BECKER side channel blowers are compact, precisely manufactured fans that are capable of reaching a flow rate of up to 1100 m3/h and a maximum pressure of around 300 mbar in the single-stage version and around 550 mbar(g) in the two-stage version. This is dynamic air compression, where a lot of waste heat is generated, but due to the minimal dimensions and compact design, these blowers can be used, for example, in water management, in the packaging industry, food industry, in the aviation industry, etc. The blowers are practically maintenance-free and reliable.

BECKER side channel blowers are compact, precisely manufactured fans that are capable of reaching a flow rate of up to 1100 m3/h and a maximum pressure of around 300 mbar in the single-stage version and around 550 mbar(g) in the two-stage version. This is dynamic air compression, where a lot of waste heat is generated, but due to the minimal dimensions and compact design, these blowers can be used, for example, in water management, in the packaging industry, food industry, in the aviation industry, etc. The blowers are practically maintenance-free and reliable.

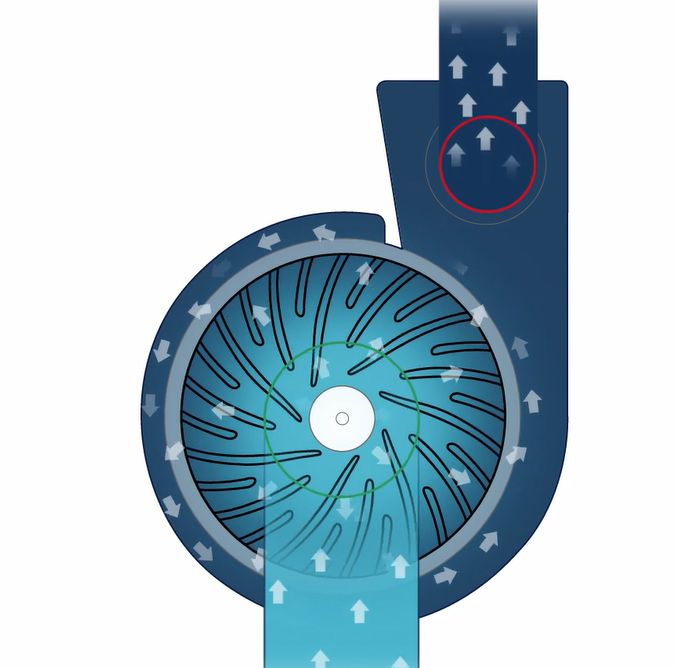

BECKER radial blowers are very special, highly efficient and quiet devices for special applications. They are highly precise production of both the centrifugal impeller and other components. The resulting compressed air is practically pulsation-free. The power is regulated by a frequency converter to maximize the efficiency of compressed air production. They are mainly used by laser manufacturers for recirculation of CO2 or other inert gases. In the food industry, this is mainly the reduction of oxygen in food to extend its shelf life, etc.

BECKER radial blowers are very special, highly efficient and quiet devices for special applications. They are highly precise production of both the centrifugal impeller and other components. The resulting compressed air is practically pulsation-free. The power is regulated by a frequency converter to maximize the efficiency of compressed air production. They are mainly used by laser manufacturers for recirculation of CO2 or other inert gases. In the food industry, this is mainly the reduction of oxygen in food to extend its shelf life, etc.

The BECKER oil-free screw blower is a special PLUG and PLAY system, which is supplied in a sound-absorbing cover, including an integrated frequency converter. These are oil-free blowers. Because there is no oil in the compression space, all thermal energy is available at the discharge, and therefore it can be recovered very effectively, for example into hot water for heating or DHW preparation. The service life of the device is very long and the payback in the case of centralization of compressed air production is not long.

The BECKER oil-free screw blower is a special PLUG and PLAY system, which is supplied in a sound-absorbing cover, including an integrated frequency converter. These are oil-free blowers. Because there is no oil in the compression space, all thermal energy is available at the discharge, and therefore it can be recovered very effectively, for example into hot water for heating or DHW preparation. The service life of the device is very long and the payback in the case of centralization of compressed air production is not long.

A blower, technically speaking an industrial blower, is designed to compress air and a whole range of other gases. In general, a blower increases the gas pressure between the inlet and outlet, and this is associated with an increase in the flow rate. Depending on what the blower is to be used for, we choose the appropriate type so that the compression of a particular type of gas is energy efficient, and most importantly so that the blower has a long service life. A blower can transport from a few units of m3/h to several tens of thousands of m3/h of gas at a certain overpressure. We usually talk about the suction pressure of the blower being atmospheric, i.e. 1013 mbar(a), or the blowers are recirculating and here it is necessary to determine the working underpressure, overpressure and flow rate.

YNNA spol. s r.o. is an authorized representative for the Czech Republic.

YNNA spol. s r.o. is an authorized representative for the Czech Republic.