Robuschi ROBOX up to 9500 m3/h

Belt-driven blowers - oil-free air compression

Highly efficient oil-free screw high-pressure blowers.

- Overpressure up to 3500 mbar abs.

- Flow up to 9500 m³/h

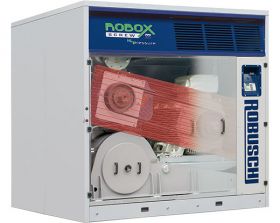

Low noise

Optimal compression efficiency is guaranteed by the innovative ROBUSCHI rotor profile and means less noise during the compression phase. Low noise is ensured by the rotational speed (max. 6000 rpm) of the rotor and the absence of a stepped gear, together with special silencers and a noise enclosure (WS version). A version without a noise enclosure (WL) is also available.

Easy installation and maintenance

As it can be transported using a forklift or pallet truck,

ROBOX offers easy installation. Connecting the electrical system is also simple

thanks to the rear panel and the SENTINEL control panel. The robust construction

of each part ensures a long service life and minimal maintenance requirements.

The simple arrangement of the unit components allows for common maintenance tasks to be carried out from the front:

- Easy oil change

- Easy oil filter change

- Easy oil pressure adjustment and intake filter change

- Easy belt change

Pressure lubrication system

The compressor is equipped with an oil pump integrated directly into the compressor, which eliminates the need for an additional electrical circuit.

High energy efficiency

The innovative and unique profile of the ROBUSCHI rotors optimizes the ratio between capacity and pressure, thanks to the maximum internal compression performance. This increases the efficiency of the ROBOX screw unit. Its characteristics ensure high efficiency (> 75%) over a wide speed range (from 100% to 25%). The high efficiency of the ROBOX SCREW plus its reduced maintenance costs guarantee a rapid return on the initial investment (on average 2 years depending on the use and operating conditions).

Flexibility

The compressor offers the possibility of regulating the power to always meet the customer's needs. It is also suitable for intermittent use with frequent starts to best suit the specific requirements of the process. The belt drive ensures the right capacity for the application and also allows the installation of a motor that is best suited to the power absorbed by the compressor (therefore operating at optimum efficiency).

Reliability

The precise design and careful selection of individual compressor components, together with the low operating speed, make the ROBOX SCREW an extremely reliable unit. The SENTINEL 2 and SENTINEL PRO control systems ensure optimal machine operation through continuous monitoring of operating parameters.

Downloads

- robox-screw_brochure_w11d17c_eng-dfa71.pdf [PDF, 3.19 MB]